CVD Zinc Sulfide (CVD ZnS)

ZnS grown by chemical vapor desposition (CVD) at the exceptional fracture strength and hardness leading to its frequent choice for harsh environments.This material is often used in the 8 to 12 microns region.ZnS has a lower cost relative to ZnSe and ZnS MS, and has potential wherever a tough and strong IR transmitting material is required.Advanced Materials’ CVD ZnS is chemically inert, non-hygroscopic, highly pure,theoretically dense, and easily machined.

Optical

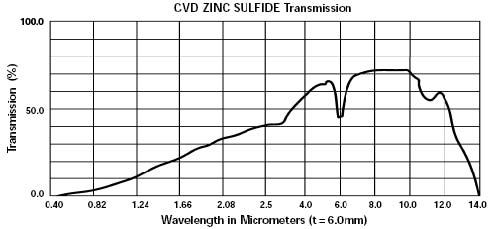

Transmission Range

1-14.0 μm

Mechanical

Young's Modulus

74.5 GPa(10.8 x 105 psi)

Bulk Absorption

<= 0.24 cm-1@ 10.6μm

Rupture Modulus

103.4 MPa (15,000 psi)

Coefficient

Knoop Hardness

210-240 kg/mm2

Temp.Change of

41 x 10-6/°C

Properties

Poisson's

0.27

Properties

Refractive Index

@ 10.6μm

Ratio

Refractive Index

< 100 x 10-5

Physical

Chemical purity

99.9996%

Non-homogeneity

@ 10.6μm

Melting Point

1830.0 oC

Thermal

ThermalConductivity

0.167W/cm/°C @ 20°C

Density

4.09 g/cm3

Specific Heat

0.469 J/g/°C

Properties

Resistivity

≈1012Ωcm

Properties

Linear Expansion

6.8 x 10-6/°C@ 20°C

Crystal

cubic

Coefficient

structure

Indices of Refraction (n) of CVD Zinc Sulfide

as a function of wavelength at room temperature (20°C)

| Wavelength | n | Wavelength | n | Wavelength | n | Wavelength | n |

| (μm) | (μm) | (μm) | (μm) | ||||

| 0.4047 | 2.54515 | 0.6678 | 2.34033 | 1.5296 | 2.27191 | 9.0000 | 2.21290 |

| 0.4358 | 2.48918 | 0.7065 | 2.33073 | 2.0581 | 2.26442 | 10.0000 | 2.20084 |

| 0.4678 | 2.44915 | 0.7800 | 2.31669 | 3.000 | 2.25772 | 11.250 | 2.18317 |

| 0.4800 | 2.43961 | 0.7948 | 2.31438 | 3.500 | 2.25498 | 12.000 | 2.17101 |

| 0.5086 | 2.41279 | 0.8521 | 2.30659 | 4.000 | 2.25231 | 13.000 | 2.15252 |

| 0.5461 | 2.38838 | 0.8943 | 2.30183 | 4.5000 | 2.24955 | - | - |

| 0.5876 | 2.36789 | 1.0140 | 2.29165 | 5.0000 | 2.24661 | - | - |

| 0.6438 | 2.34731 | 1.1287 | 2.28485 | 8.000 | 2.22334 | - | - |

|